Valdese Weavers has been working with recycled yarns for nearly 20 years but in a bid to elevate its sustainability profile, the company turned to the SEAQUAL INITIATIVE based in Spain.

A leading fabric and textile producer that has been manufacturing residential and contract textiles for the furniture market in the foothills of North Carolina for more than 100 years, Valdese Weavers is widely considered to be an industry leader for designing and innovatively weaving beautiful decorative fabrics.

While the company takes pride in being a Made-in-USA manufacturer, one of its loftier goals has been to minimize its impact on the environment and the planet’s natural resources.

Valdese Weavers has used yarns recycled from plastic bottles for the past two decades to produce its environmentally-conscious products, especially in its contract division, but company officials began searching a few years ago for new ways to expand their sustainability efforts and achieve more innovative, sustainably-minded solutions to attack the existing problem of ocean pollution.

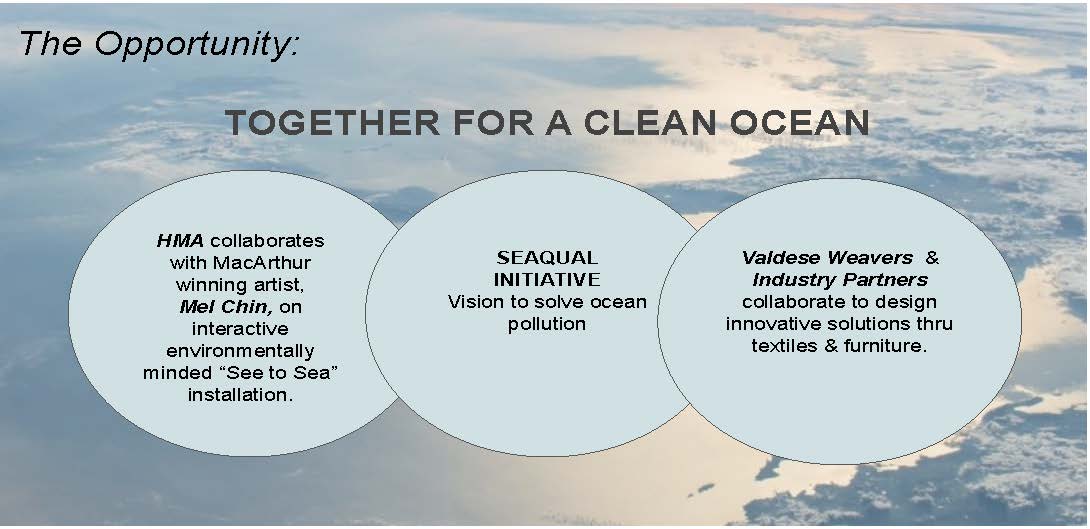

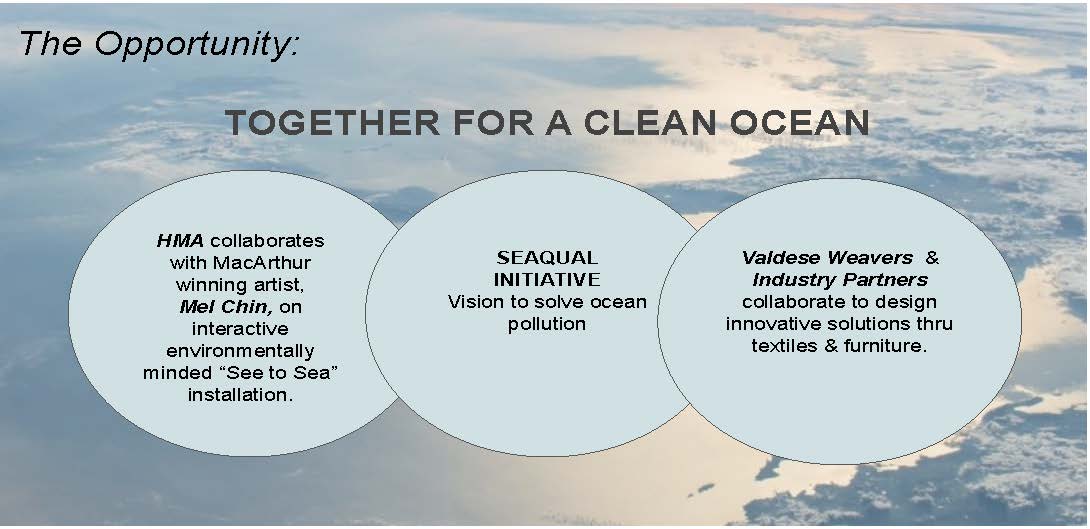

Fast forward to today and the journey has led Valdese to a dizzying array of new initiatives, including: a licensing arrangement with a Spanish non-profit organization named the SEAQUAL INITIATIVE; the launch of a new line of performance fabrics made from recycled ocean fabrics, InsideOut Performance Fabrics®; a collaboration with an award-winning artist; and a museum exhibit that opened on Friday (Nov. 4) at the Hickory Museum of Art in Hickory, N.C.

Fast forward to today and the journey has led Valdese to a dizzying array of new initiatives, including: a licensing arrangement with a Spanish non-profit organization named the SEAQUAL INITIATIVE; the launch of a new line of performance fabrics made from recycled ocean fabrics, InsideOut Performance Fabrics®; a collaboration with an award-winning artist; and a museum exhibit that opened on Friday (Nov. 4) at the Hickory Museum of Art in Hickory, N.C.

“We have been trying to find next steps of sustainability in terms of materials for several years,” says Christy Almond, vice president of product development and marketing at Valdese Weavers. “We have said ‘no’ to a lot of product material ideas that did not have an authentic story or durability, did not meet where we felt industry was headed, had inconsistent supply chains, or the price was out of line.”

In 2018, Valdese discovered the SEAQUAL INITIATIVE. After studying the non- profit organization’s mission, Almond says Valdese determined it could “take our recycling story to the next level.”

This organization founded on creating a collaborative community against pollution has brought together an extensive network of individuals, organizations, and companies “working together to help clean our oceans, raise awareness of the issue of marine litter and highlight those helping to fight it.”

“Their goal is to organize the individual organizations, cleanup committees and fishermen to bring their cleanup efforts together to incentivize them, clean up oceans, collect ocean trash, and use collective power to go to recycling agencies to process products and sort through it to use materials that can ultimately be upcycled,” Almond explains.

To view the entire process—from collection of ocean plastic waste to the production of the end product of Valdese Inside Out Performance fabrics, click here.

“When we met with SEAQUAL before COVID they were in 42 countries and now they are in 60 countries,” Almond says. “The amount of waste and upcycled materials has dramatically increased. We know they are making a difference.”

SEAQUAL has processed 600 tons of marine litter from the ocean. Of that total, the organization has transformed 200 tons of plastic into upcycled marine plastic and yarn for companies like Valdese to use.

SEAQUAL has processed 600 tons of marine litter from the ocean. Of that total, the organization has transformed 200 tons of plastic into upcycled marine plastic and yarn for companies like Valdese to use.

“They actually embed the yarn with tracers, so that they know it is authentic. They are very serious about that process and they have certification at each of the steps in the supply chain that companies must adhere to,” Almond says. “As their network cleanup committees and processing grows, we are hoping that is going to continue to increase as more material becomes available.”

Hundreds of global brands and retailers are listed as licensing partners with SEAQUAL on its website, including such well-known retailers as American Eagle Outfitters, Bed Bath and Beyond, and Ikea.

“We had seen a lot of different ocean plastic stories out there. No one had this multi-faceted story about cleaning up the ocean, upcycling and properly disposing of the trash,” she said. “It’s one thing to sift through and take out the parts that you want, but you are not really making a difference.”

SEAQUAL, on the other hand, properly disposes of the ocean materials that are not recyclable.

“Taking on new yarn SKUs is an investment. To meet their 20 percent content, we had to invest in the right tools to get that content assured. In terms of raw materials, we felt like it was in line with our existing cost structure,” Almond notes.

Valdese Weaver’s goal is to expand development with SEAQUAL and bring awareness to the initiative and “challenge our industry to think about sustainable materials.”

“Just regular upcycled plastic is not enough,” Almond notes. “How do we move this journey forward? More needs to be done.”

One way to move the story forward is to partner with an award-winning artist and amplify the story to the public.

SEAQUAL and Valdese Featured in Museum Exhibit

That’s just what Valdese and SEAQUAL have done.

Valdese is collaborating with MacArthur Genius Award winning artist, Mel Chin, as part of an exhibit at the Hickory Museum of Art in Hickory, N.C. “to promote the power of design to fuel change in our industry.”

Chin, an ecologically and environmentally-minded artist, has been behind projects seeking to raise awareness on issues such as contaminated soil in New Orleans and abandoned homes in Detroit.

The Hickory Museum of Art has opened a new exhibit highlighting the problem of ocean pollution, in conjunction with an experiential exhibit, SEA to SEE, that has been created by Chin and is housed at the Mint Museum in Charlotte.

The Valdese exhibit at the Hickory Museum showcases the company’s partnership with the SEAQUAL INITIATIVE and explains how the company and the furniture industry is working together to help solve the problem of ocean pollution.

The Valdese exhibit at the Hickory Museum showcases the company’s partnership with the SEAQUAL INITIATIVE and explains how the company and the furniture industry is working together to help solve the problem of ocean pollution.

“We bring so many people through our facility to train them on the textile process, including salespeople with furniture manufacturers, furniture dealers, and large-scale retailers. These are big companies that are trying to help their sales team understand how to sell fabrics. I thought it would be great to connect our SEAQUAL story with what is happening at the museum and tell a bigger picture story about how the industry is using design to propel change,” Almond says.

“Textiles get a bad rap, not just in terms of manufacturing, especially if you’ve grown up in a textile town. You’ve seen and heard people lose jobs that go to China, or say that furniture is not a reliable career, or that furniture is not an innovative industry,” she adds.

“We wanted this exhibit to highlight technology and design and innovation and cool things happening in this community that are impacting not just Hickory but the United States.”

Fast forward to today and the journey has led Valdese to a dizzying array of new initiatives, including: a licensing arrangement with a Spanish non-profit organization named the SEAQUAL INITIATIVE; the launch of a new line of performance fabrics made from recycled ocean fabrics, InsideOut Performance Fabrics®; a collaboration with an award-winning artist; and a museum exhibit that opened on Friday (Nov. 4) at the Hickory Museum of Art in Hickory, N.C.

Fast forward to today and the journey has led Valdese to a dizzying array of new initiatives, including: a licensing arrangement with a Spanish non-profit organization named the SEAQUAL INITIATIVE; the launch of a new line of performance fabrics made from recycled ocean fabrics, InsideOut Performance Fabrics®; a collaboration with an award-winning artist; and a museum exhibit that opened on Friday (Nov. 4) at the Hickory Museum of Art in Hickory, N.C.

SEAQUAL has processed 600 tons of marine litter from the ocean. Of that total, the organization has transformed 200 tons of plastic into upcycled marine plastic and yarn for companies like Valdese to use.

SEAQUAL has processed 600 tons of marine litter from the ocean. Of that total, the organization has transformed 200 tons of plastic into upcycled marine plastic and yarn for companies like Valdese to use. The Valdese exhibit at the Hickory Museum showcases the company’s partnership with the SEAQUAL INITIATIVE and explains how the company and the furniture industry is working together to help solve the problem of ocean pollution.

The Valdese exhibit at the Hickory Museum showcases the company’s partnership with the SEAQUAL INITIATIVE and explains how the company and the furniture industry is working together to help solve the problem of ocean pollution.

U.S. Trade Representative Sarah Bianchi made an inaugural trip to meet with U.S. textile manufacturers in the New England area in late February, where she toured Shawmut Corp.’s state-of-the-art manufacturing facility in West Bridgewater, Mass. and participated in a substantive textile industry roundtable discussion with NCTO member executives.

U.S. Trade Representative Sarah Bianchi made an inaugural trip to meet with U.S. textile manufacturers in the New England area in late February, where she toured Shawmut Corp.’s state-of-the-art manufacturing facility in West Bridgewater, Mass. and participated in a substantive textile industry roundtable discussion with NCTO member executives.

Visit NCTO.org and our Twitter, Facebook, Instagram and LinkedIn pages to learn more about these pressing issues.