A recent documentary has explored US nearshoring, and Kristi Ellis, VP of communications at the National Council of Textile Organisations (NCTO) believes it is closer than ever to becoming a reality, but policy is needed to secure its long term sustainability. (Read the column on Just Style here.)

By Guest Author

Nearshoring, probably a pipe dream for many US brands just a short while ago, is now closer than ever.

The Financial Times and its global business columnist, Rana Foroohar, have produced one of the most honest and accurate portrayals of the adverse effects of globalisation on US textile manufacturing over the past two decades, while capturing the industry’s current renaissance in the wake of the Covid pandemic.

In this documentary film entitled “Manufacturing in America, postglobalisation,” Foroohar looks at why the US should bring manufacturing jobs back home and highlights the existing textile industry which has played an instrumental role in supplying thousands of products for all industrial segments, the military, consumer market, and personal protective equipment (PPE) to the public and private sector.

In the second of three films, based on her new book, “Homecoming: The Path to Prosperity in a Post-Global World,” Foroohar follows the all-American supply chain of clothing company American Giant to see how it impacts jobs, businesses and communities.

American Giant CEO and founder Bayard Winthrop, Parkdale chairman and CEO Anderson Warlick, Carolina Cotton Works president Bryan Ashby, and National Council of Textile Organizations (NCTO) president and CEO Kim Glas, among others are all featured in the newly release film.

“I wanted to make this film about US manufacturing, because I believe that we are at a turning point. Since the 1980s manufacturing jobs have plummeted. In the constant drive to make things cheap, factories and jobs were moved overseas. Textiles were hit especially hard,” Foroohar says in the opening of the film. “But I want to show you how post pandemic there is a new regionalisation of industry taking place. And jobs are starting to move back. It’s about being focused not on what is cheapest but about creating better jobs for local communities.”

Globalisation’s impact and the China Effect

The film opens in a cotton field in North Carolina and takes us on a US manufacturing journey stretching from the field to all points in the production chain and finally to a store shelf in New York.

It is a narrative within a broader narrative about how “prioritising efficiency over resilience, and profits over local prosperity, has produced massive inequality, persistent economic insecurity and distrust in our institutions,” which was expertly outlined in Foroohar’s new book.

Foroohar provides new arguments on why a post-global industrial strategy is needed and the “rise of local, regional and homegrown business is now at hand.”

Thirty years ago, the US was leading the textile sector, Foroohar explains in the film, but globalisation advocates and forces coupled with other seismic international trade actions, such as China’s accession to the World Trade Organization (WTO), exacted a heavy toll on the US manufacturing sector.

“What we were told was that we needed to normalise our relationship with China so that they would play by the rules,” says Glas in the film. “So their accession to the WTO, granting them Permanent Normal Trade Relations (PNTR) status — there’s nothing normal about it. We have suffered greatly.”

On globalisation and China’s accession to the WTO former US trade representative ambassador Robert Lighthizer notes: “There was this kind of hubris that the world had changed and that market forces forever now were going to move us in the direction of economic growth and freedom throughout the world and all these notions, which were lovely except they just don’t exist.”

Foroohar notes that many in the US manufacturing sector “feel that free trade was never really free, because it didn’t account for the lower labour and environmental standards that allowed a lot of countries overseas to make things more cheaply.”

“Free trade is about price optimisation and consumption,” Lighthizer says. “I think the important thing is production. Production leads to good jobs, good wages and solid fundamental American communities.”

Lighthizer believes the drive to globalisation saw the US effectively giving away its prosperity, Foroohar notes.

“If there is a sacrifice of a price of a T-shirt or your third television set, in order to have strong communities in America, that’s the sacrifice that I’m willing to make,” Lighthizer adds.

On globalisation and access to US markets, Parkdale chairman and CEO Anderson Warlick notes: “This is the largest economy in the world and the price of admission is not that high and it should be. They should pay their share just like every American taxpayer.”

It’s like letting other athletes start a 100-metre race closer to the finish line, she says citing Warlick.

“Competition is good and Americans thrive on competition. Now free trade? That’s a unicorn I’ve been chasing for 30 years, trying to find anybody in the world that practiced it,” Warlick says. My best way of describing it is, it’s economic treason.”

Resurgence of resilient nearshoring US textile supply chain

Yet, even as companies rushed to offshore production, gutting the US manufacturing sector’s workforce, a core industry remained here and thrived.

The film focuses on one US company’s perseverance and success, under the leadership of American Giant’s CEO Winthrop.

“The original idea behind the company was to reclaim the very high quality American-made stuff. I had felt that… the care and the passion and skill and craft and work that goes into making a product was not just important from an understanding about how you build quality product but emotionally important and societally important,” Winthrop says.

“The idea that there isn’t a good textile capability in the United States anymore is nonsense.”

Foroohar observes that American Giant’s supply chain encompasses cotton gins, mills, knitting and sewing factories all within a 120-mile radius.

“That not only cuts down on shipping costs. It also means he knows his clothing is in line with American environmental and labour standards.

For Bayard, it’s about keeping relationships and expertise close to home.”

Winthrop embraces that proximity to the entire supply chain, noting that standing in a cotton field talking to farmers about varietals and crop production is critical. “It’s creating that connection to the men and women involved in highly complicated processes of making the things we consume today.”

For Parkdale Mills, a major cotton yarn spinner and supplier to American Giant, “it’s all about being able to compete in a global marketplace, leveraging efficient production in the US to go up against the cheap cost of labour overseas,” Foroohar explains.

“We invest heavily in technology to create better efficiencies, to create better quality, roughly US$500m in the last 10 years to create more automation to have the latest, greatest equipment to prepare the fibre and to spin the yarn,” says Davis Warlick, executive vice president of Parkdale.

Warlick adds, “We are constantly striving to make things more automated in order to compete, I think that’s been one of the reasons we are still here.”

Cautious optimism prevails in the US textile industry. The pandemic and ensuing global supply chain crisis has turned the long-standing global sourcing paradigm on its head, forcing retailers and brands to diversify out of China and move production closer to home. And that is driving a renewed sense of optimism.

But Bryan Ashby, president of Carolina Cotton Works, stresses that policymakers must provide a long-term commitment to building the domestic supply chain.

“It’s great for a politician to stand in front of a microphone and say: ‘Let’s bring jobs back to America,’ but show us the commitment by giving us some sort of reason to believe that 18 months from now the narrative doesn’t flip and we all of a sudden want to sell industries out.”

One need look no further than the latest US government trade data as evidence that onshoring and nearshoring is ticking upward.

“We have seen historic investment in the US textile production chain as well as in our Central America free trade agreement partners, including Honduras, Guatemala, and El Salvador,” Glas said. “We expect over $1bn of new investment to go into Central America this year alone for textiles. That’s an indication the world’s changed.”

About the author: Kristi Ellis is vice president of communications at the National Council of Textile Organizations (NCTO). The NCTO is an association that is the voice of the entire spectrum of the textile industry. There are four separate councils that comprise the NCTO leadership structure, and each council represents a segment of the textile industry and elects its own officers who make up NCTO’s board of directors.

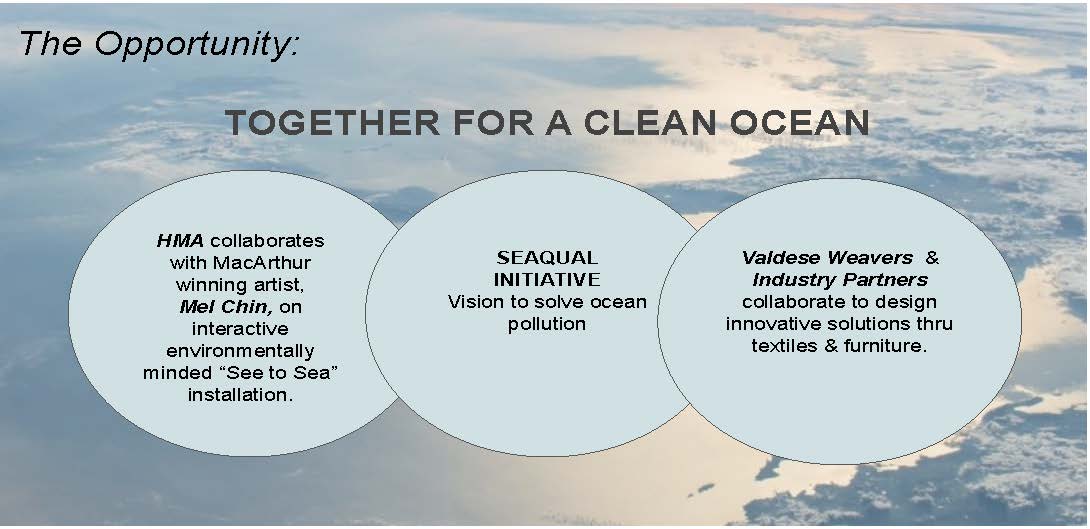

Fast forward to today and the journey has led Valdese to a dizzying array of new initiatives, including: a licensing arrangement with a Spanish non-profit organization named the SEAQUAL INITIATIVE; the launch of a new line of performance fabrics made from recycled ocean fabrics, InsideOut Performance Fabrics®; a collaboration with an award-winning artist; and a museum exhibit that opened on Friday (Nov. 4) at the Hickory Museum of Art in Hickory, N.C.

Fast forward to today and the journey has led Valdese to a dizzying array of new initiatives, including: a licensing arrangement with a Spanish non-profit organization named the SEAQUAL INITIATIVE; the launch of a new line of performance fabrics made from recycled ocean fabrics, InsideOut Performance Fabrics®; a collaboration with an award-winning artist; and a museum exhibit that opened on Friday (Nov. 4) at the Hickory Museum of Art in Hickory, N.C.

SEAQUAL has processed 600 tons of marine litter from the ocean. Of that total, the organization has transformed 200 tons of plastic into upcycled marine plastic and yarn for companies like Valdese to use.

SEAQUAL has processed 600 tons of marine litter from the ocean. Of that total, the organization has transformed 200 tons of plastic into upcycled marine plastic and yarn for companies like Valdese to use. The Valdese exhibit at the Hickory Museum showcases the company’s partnership with the SEAQUAL INITIATIVE and explains how the company and the furniture industry is working together to help solve the problem of ocean pollution.

The Valdese exhibit at the Hickory Museum showcases the company’s partnership with the SEAQUAL INITIATIVE and explains how the company and the furniture industry is working together to help solve the problem of ocean pollution.